SULB commissions SMS group for the modernization of an electric arc furnace and a four-strand continuous caster for billets and beam blanks

- Focus on environmental steel production, improving quality requirements and increasing productivity

- Modernization reduces energy consumption and iron oxide content in the slag

- CONDOOR® slag door improves safety for the operating personnel

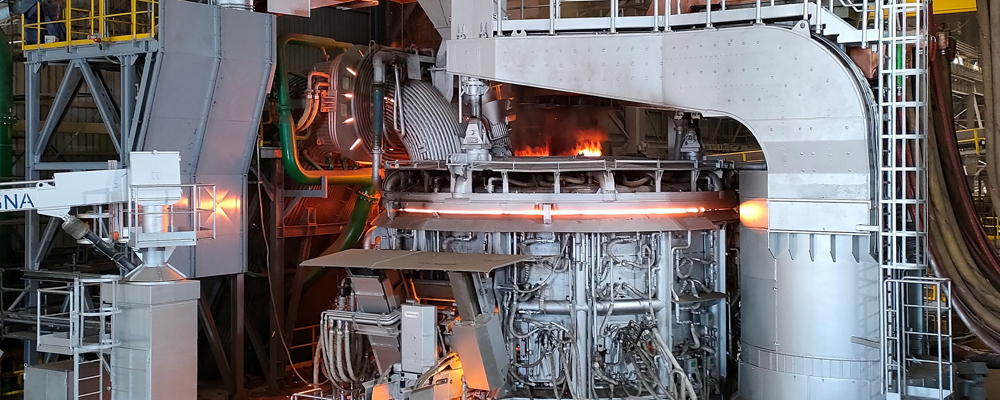

SULB Company BSC located in the Kingdom of Bahrain commissions SMS group (www.sms-group.com) for the revamp of the 130 ton electric arc furnace (EAF) and the modernization of the four-strand continuous caster for the production of billets and beam blanks. The main motivation for this project is to increase the safety and to enhance the efficiency and productivity. That will make ultimately lead to an upgraded quality of the products possible. The start of production is planned in 2024.

The SULB Bahrain plant, located in Hidd industrial area, has a melt shop and a medium and heavy section rolling mill supplied by SMS, encompassing the whole process from DRI to finished steel.

As part of the EAF modernization, a CONDOOR® slag door is to install. The aim of the upgrade is to improve the furnace seal and thus to increase productivity. The installation of the CONDOOR® slag door enhances safety for the operating personnel as the slag cleaning of the breast is performed automatically. The slag removal by forklift is no longer required. The modernization reduces specific energy consumption and increases production yield. Moreover, the iron oxide content in the slag is significantly reduced.

The four-strand continuous caster is designed for the production of six section sizes. The modernization goal is to increase casting speeds and productivity through additional cooling and strand support in the upper segments. The modernization scope includes the rebuild of segment 1 for bloom and beam blank sections, including a new spray cooling system, water deflectors, a new hydraulic system and an expanded steam extraction system. This caster modernization provides SULB with more production flexibility and thus the ability to respond more effectively to market demand.

“We chose SMS group because we trust SMS’s leading technology and their excellent team. We have a long-standing and good partnership. At SULB, we focus on environmental steel production and SMS’s know-how and equipment have helped us and will continue to help us to constantly improve our quality requirements, increase our productivity and environmental sustainability”, says Ravi Singh, Chief Executive Officer of SULB Company.

SULB is a Middle East region’s fully integrated medium and heavy beams and structural steel sections producer, and a joint venture between Foulath Holding BSC and Japan’s Yamato Kogyo Co., Ltd, a beams and structural sections producer. SULB operates two plants, one in the Kingdom of Bahrain in Hidd and one in the Kingdom of Saudi Arabia in Jubail. The plant in Jubail is a light-to-medium steel section mill, also supplied by SMS group.