ZUMBACH Electronics - Switzerland equips Hot Rolling Mill with PROFILEMASTER® Profile Measuring System at Hoesch Schwerter Profile GmbH - Germany

ZUMBACH Electronics of Switzerland recently sold a PROFILEMASTER® SPS 800-S8 profile measuring system to the German based company Hoesch Schwerter Profile GmbH.

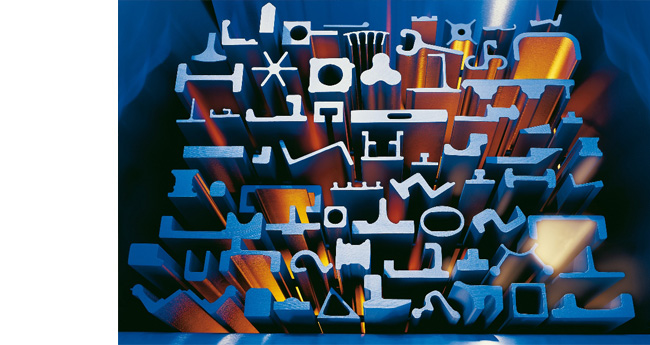

Hoesch is part of the Italian Calvi Holding group and produces various steel profiles on their hot rolling mill. The company is a manufacturer of customized special profiles made of steel. These are used in virtually all areas of the steel processing industries.

ZUMBACH is a leading supplier of non-contact measurement solutions for the steel industry as well as other industries such as wire and cable, plastics and rubber.

Hoesch’ partnership in choosing ZUMBACH, trusting on their long experience in the field of non-contact measurement technology allows them to make a huge leap forward in manufacturing capability benefiting from the latest in technological advantages.

For ZUMBACH, Hoesch is an ideal partner because the company focuses on quality, precision and close customer relationships – Virtues for which also ZUMBACH vouches for.

In order to reach the increasing demands of accuracy and reliability of steel profiles and to increase the efficiency of the hot rolling mill, Hoesch decided to acquire a PROFILEMASTER® SPS 800-S8 system. Thanks to this measuring system, Hoesch will have a more competitive position in the market. Amongst other benefits, start-up and changeover times can be extensively reduced.

Main System Advantages and Features

- 8 cameras which can be equipped modularly, any shape can be captured and measured

- Up to 16,000 points / contour (2,048/camera) = 5,734,400 points/second

- High sampling rate of 350…500 / second (Full profiles / second)

- 4 different colors of the lasers à No interference

- Easy and quick calibration check (can be done by the customer within few minutes)

- Real time monitoring of complex profiles

- Special mode for roundness/polygonality of rounds

- Shape fault detection (SFD) thanks to high sampling rate

- High sampling rate of 500 / second

- Compilation of a 3D model thanks to high sampling rate

- Highly accurate measurements

- Detects process problems in an early stage

- Reliable operation at harsh mill conditions up to 1200° C (2192° F)

- Simple cleaning, short maintenance

- Logging of all production data for QC department

- Networking capability with a higher level system

- Makes post production measurements irrelevant

Advanced Software

Creation of measurement recipe with Zumbach software (PROFILEDEFINER)

- Customer can load the profile via its own DXF file (from CAD construction)

or

- By means of the “Product Generator”: predefined forms (round and rectangular) allow quick “read in” of any product with round or rectangular size