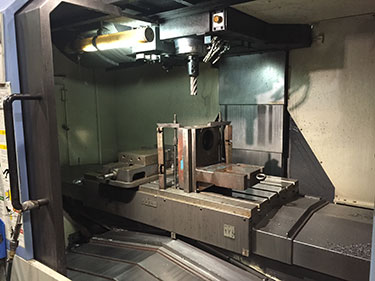

New Doosan DNM 650 milling center

Romeoville, IL - Roll Machining Technologies and Solutions, as part of its 2014 massive infrastructure improvements added a new Doosan DNM 650 milling center. This new milling center is equipped with a powerful spindle motor providing superior performance in our type of manufacturing environment. The machine features an 18.5kW 12,000rpm direct drive spindle (40 taper), 30-position tool changer and the Fanuc i-series control, and a 1,300mm x 670mm table. The new milling center is designed for exceptional high accuracy and minimized thermal displacement and vibration. A key main feature of the unit is the Rapid Traverse. Linear motion guides way and high speed servomotors apply high rapid axis movement. This reduces non-cutting time and machining time for greater productivity. It is equipped the thru spindle high pressure coolant system for accurate deep hole drilling. This reduces cycle times while keeping the work piece structural integrity intact. RMTS President Rick Olson states, "We maintain a high level of commitment to reinvest in our company and by purchasing new equipment with our infrastructure expansion, this demonstrated our commitment to our customers as well. Improved accuracy and faster turn around times are what our customers depend on. This is a win-win for RMTS and our customers."