Silva Mash orders welded tube mill from Danieli

The new high-productivity ERW line will produce niche tubular products mainly for high-end automotive and furniture applications

With an actual capacity of 60,000 tpy of high-quality tubes delivered to the main European automotive and furniture manufacturers, Silva Mash is one of the largest welded tube producers in Bulgaria.

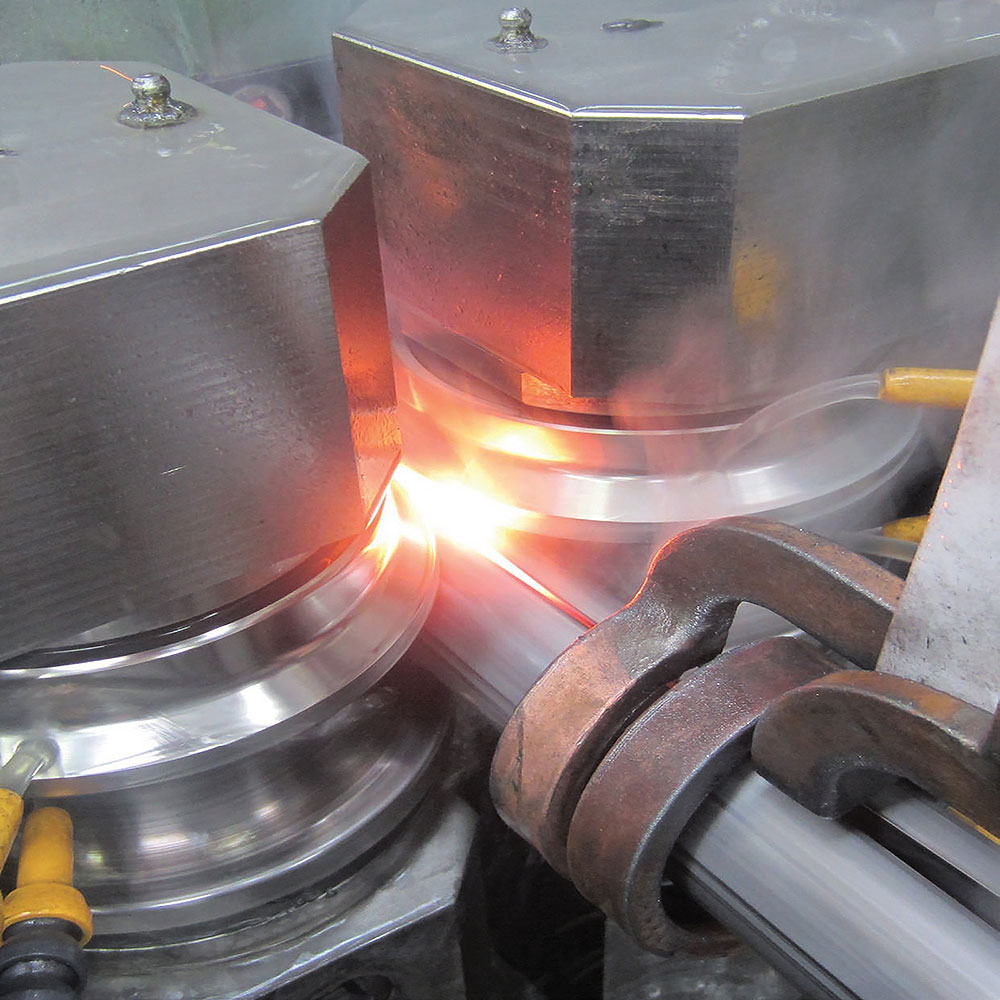

The new Danieli W+K "ERW 45/2.5-150" mill is designed to produce round, rectangular, square, semi-oval and elliptical high-quality and high-strength tubes with superior surface finishing, ODs ranging from 10 to 45 mm and WTs from 0.5 to 2.5 mm.

With a velocity reaching 150 m/min, the new line is able to offer superior diameter/wall thickness ratio capability which along with quick product change-over time (less than 60 min) results in great product flexibility.

In order to achieve the high level of productivity requested, the line is composed of an entry line with a double decoiler, strip joiner, horizontal accumulator, heavy duty forming section with break-down, fin pass, welding and sizing stands, a cut-off and evacuation system including a packaging machine.

Simplified, cost effective ERW mill configurations are also available for commodity tube producers.